Autumn time is harvest time – and that’s particularly true for wine grapes. But, what happens to all the bunches of grapes after they’ve been picked? How are they transformed into wine? Take a look at our picture gallery and learn all about the different stages in the production of red wine.

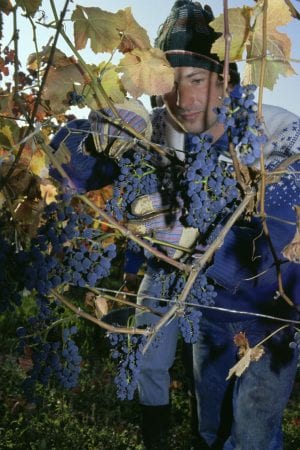

The ripe, purple/black grapes are carefully cut from the vine using secateurs.

If the end product is a high quality wine, harvesting will always be done by hand to prevent damage to the grapes.

Any seemingly unripe or rotten grapes are identified and cut out from the harvest right away in the vineyard.

The ripeness of the grapes is tested repeatedly. This is done by testing a little grape juice in a device called a refractometer.

This optical instrument reveals the sugar content of the juice – and thus the ripeness of the grapes – on the basis of the juice’s refractive index as light passes through it.

The handpicked grapes are transported from the vineyard in special baskets…

… and are taken, without delay, for immediate processing into wine.

The first step involves the grapes being put in a machine that removes the stalks and bunch stems, and then slightly crushes the individual grapes.

So, from a great mass of grape bunches with stalks…

… come individual grapes, from which a little juice is obtained. This mixture of crushed grapes and juice is called a ‘must’.

The fermentation vats are then filled with the must.

Alcoholic fermentation begins in the vat; either of its own accord from the yeasts that are naturally present on the grapes or by the addition of cultured yeast. Fermentation not only converts the sugar in the grapes into alcohol, it also generates carbon dioxide and heat, and these need to be released from the fermentation barrel.

Another important aspect of fermentation is the release of colourings from the grape skins, which has to occur if an intensely coloured red wine is to be produced. And, so that the grapes that float on the surface always have sufficient contact with the fermentation must, now and again some of the juice is drawn from the bottom of the vat and pumped over the skins…

… an alternative and more laborious method is to manually submerge the floating grape skins and thereby incorporate them into the must.

When alcoholic fermentation is complete, the grape must go into a wine press.

Wine pressing is usually carried out using a modern pneumatic press, in which the pressure can be set very precisely to ensure an extremely gentle pressing process. Amongst other considerations, it is very important that the grape seeds are not crushed.

The young wine derived from pressing then has to be matured in a wine cellar; this is known as aging.

Less complex wines are aged in stainless steel tanks, whilst higher quality red wines are aged in wooden barrels.

Germany’s traditional wooden barrels have volumes ranging from 600 to 1200 litres. For particularly fine red wines, a smaller, French-style Barrique barrel is used, which has a capacity of just 225 to 300 litres.

During ageing the vintner constantly monitors the condition of the wine. Although laboratory analyses are an important source of information, sensory evaluation continues to be indispensable. Among other things, the vintner is checking to see whether the conversion of bitter malic acid into milder lactic acid has fully taken place during the ageing process.

After a time, the fine yeasts that remain after fermentation settle to the bottom of the barrel. The winemaker now draws off the clear wine from above this residue in a process known as racking.

The length of the ageing process depends on the type and quality of the wine; it can last from a few weeks up to eighteen months, or more. In France they call this ageing “Élévage”, literally “bringing up”. Only when the vintner feels that the wine is properly mature and has completed its ageing in the barrel , then only it is ready for bottling; and ready to fill the glasses of wine lovers everywhere! Cheers!

If you have enjoyed this post, then why not subscribe to our newsletter? Perhaps you have questions about Liebherr design? Then, please write to us! Use the comment function below this post or discuss it with us on Facebook.