Why do sounds occasionally emanate from a fridge? And what is a sound jury? At Liebherr, we are constantly working on making fridges quieter and quieter. The best examples of this are the silent models which are barely audible thanks to their special design.

Sources of noise in a fridge

It is quite normal for a fridge to make noises occasionally. In the past, a fridge usually had just a compressor and a thermostat. From time to time, the thermostat signalled to the compressor when it needed to “start up” in order to keep the temperature in the interior constant. However, modern fridges now have far more technology inside them, and this is partially responsible for the unusual noises which are perceived as disturbing. Possible sources of noise include:

- BioFresh modules with ventilation and air flaps

- NoFrost modules with ventilation and defrost heaters

- Multi-zone controls with control valves in the refrigeration circuit, etc.

In addition, the refrigerant in the refrigeration circuit assumes different aggregate states (gaseous to liquid) and, in extreme cases, passes through temperature differences of +80 °C to -45 °C. Due to the physical processes involved (expansion, contraction) this can, naturally, also cause specific noises.

The “fridge whisperer”

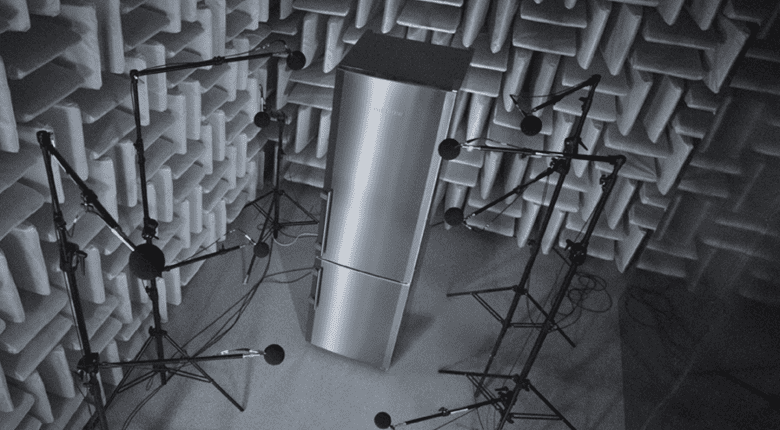

What does Liebherr Appliances actually do to eliminate these noises or, at least, minimise them? Liebherr’s engineers and developers are continually doing a great deal to reduce the noise of fridges. Appliances were being X-rayed as early as the 1980s to identify the injection noises of the refrigerants in the appliance. Acoustics research at Liebherr has made steady progress over the years; the appliances are now subjected to special tests in state-of-the-art sound measuring rooms to locate the sources of noise and then to take appropriate measures for their reduction. In the sound measuring rooms, we start “bugging” our appliances, so to speak, by listening very carefully.

Three examples of how Liebherr reduces noise:

- Speed-controlled compressors – while conventional compressors run at approx. 3,000 rpm, speed-controlled models get by with 1,000 to 1,600 rpm in standard operating mode. The low speed also reduces the noise from the appliance.

- Speed-controlled fans – similar to the compressors, the fans are also speed-controlled. Therefore, they only run as frequently and as fast as necessary to keep the interior temperature constant.

- CFC-free refrigerant R600a – the refrigerant R600a needs less pressure than other refrigerants at the same temperature. As a consequence, less force is required by the technology in the refrigeration circuit, which in turn reduces noise.

Tested by the audience: the Liebherr sound jury is listening

In order to keep reducing the sound emitted by our appliances, it’s not just acoustic engineers who are working at Liebherr to minimise noise. A special “sound jury” – consisting of colleagues who are not from the development department – listens very carefully in a test phase, i.e. before a new appliance comes onto the market. It gives the developers feedback on how the jury perceived the noise and in which respects the acoustics could still be improved. In this way, we ensure that the sound sensibility of an independent group is taken into account. This enables us to continuously optimise our appliances.

People have become more noise-sensitive

At this point, however, it should also be mentioned that the perception of sound by people has changed and many are now much more sensitive to noise. A reason for this is, among other things, the way in which low-energy buildings are built today. Due to legal requirements, the exterior walls and windows are well insulated. Consequently, hardly any noise from the outside penetrates into the dwelling so that the noises in the interior, such as those of domestic appliances, are perceived much more intensively.

We hope you enjoyed this article. Please feel free to share it across social media… We’re on Facebook, Instagram, Twitter and Pinterest.